Wilhelm T & P is the right contact for consultation on systems in the plastics processing industry. We have been working with leading international machine manufacturers for decades. This allows us to guarantee our customers the best quality and reliable service. We have been representing company Weber successfully since 2008.

WEBER is a medium-sized family-owned company that has been active in mechanical engineering for almost a century and has earned an excellent reputation for its perfection. Customers around the world are impressed by the high quality and reliability of WEBER's extrusion technology as well as wood and metal grinding machines. By combining expert knowledge and innovative technologies, the company is able to meet the needs of its customers. WEBER continuously conducts market research to closely examine target markets and address current trends with new solutions that promote efficiency and innovation.

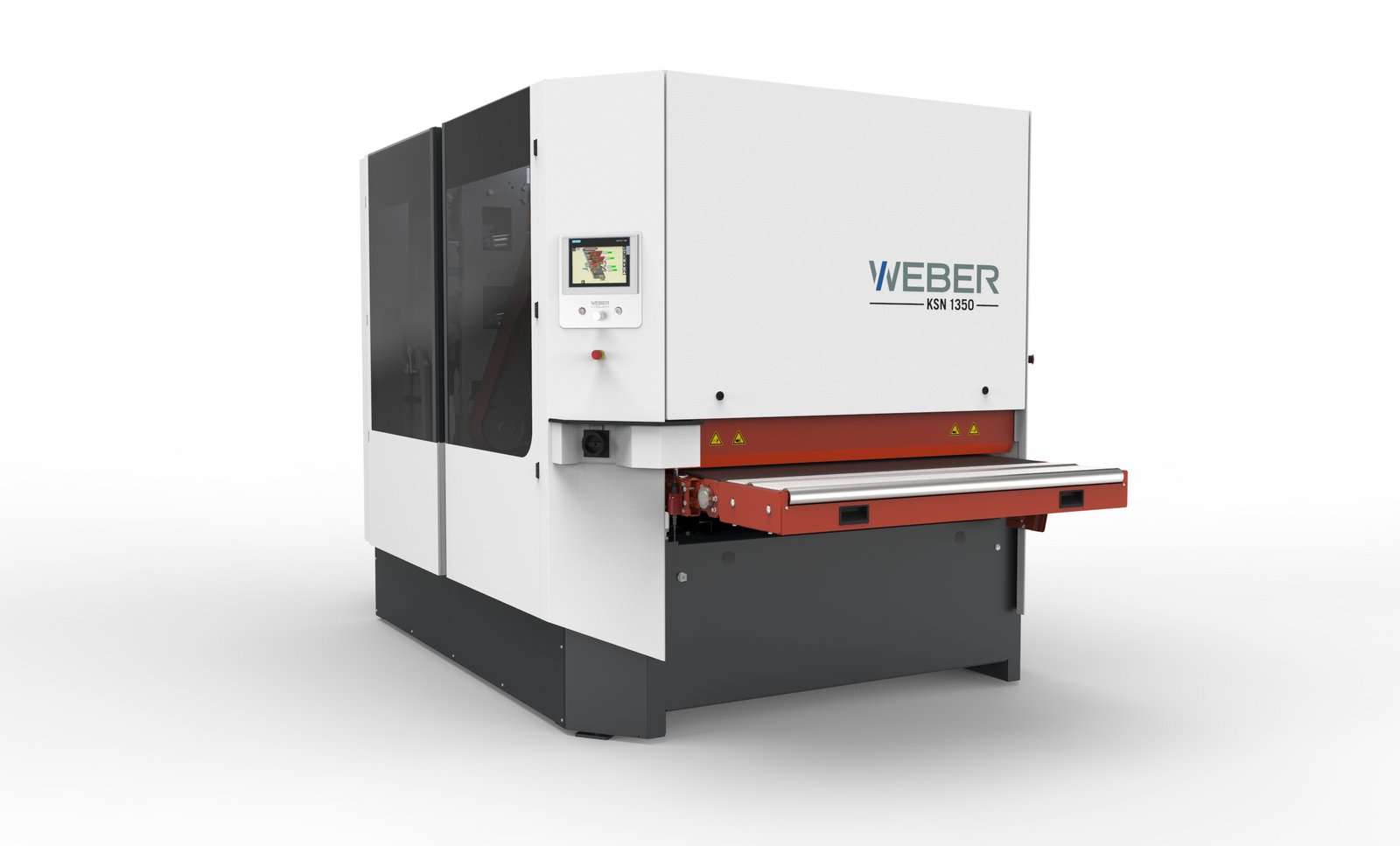

The automatic sanding machine from WEBER for wood sanding, veneer sanding and lacquer sanding

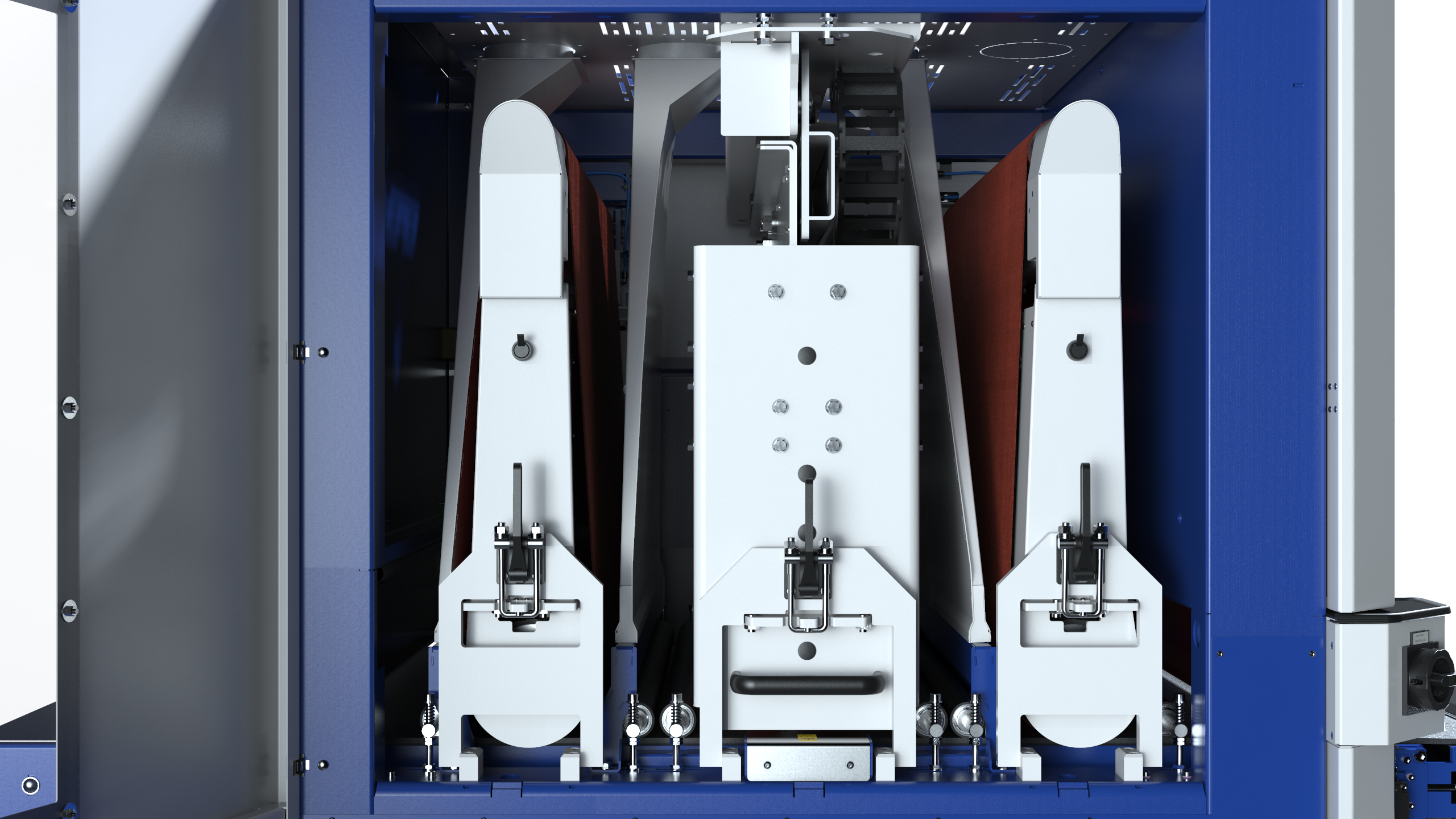

The WEBER KSN series was specifically designed for wood, veneer, and paint sanding applications in the crafts and industry sectors. The machine has up to 4 sanding stations, providing a wide range of processing options. Integration of all WEBER sanding and brushing stations is possible in any order. The WEBER KSN impresses not only with its attractive design, which showcases a new dimension of wood sanding technology, but also with clear lines and thoughtful ergonomics. Therefore, it is one of the most modern sanding machines on the market. The diagonal arrangement of the control terminal allows for quick and easy access, while all connections are installed from above. A large viewing window provides an unobstructed view of the processing stations, and easy accessibility to all electronic and mechanical parts makes maintenance easier.

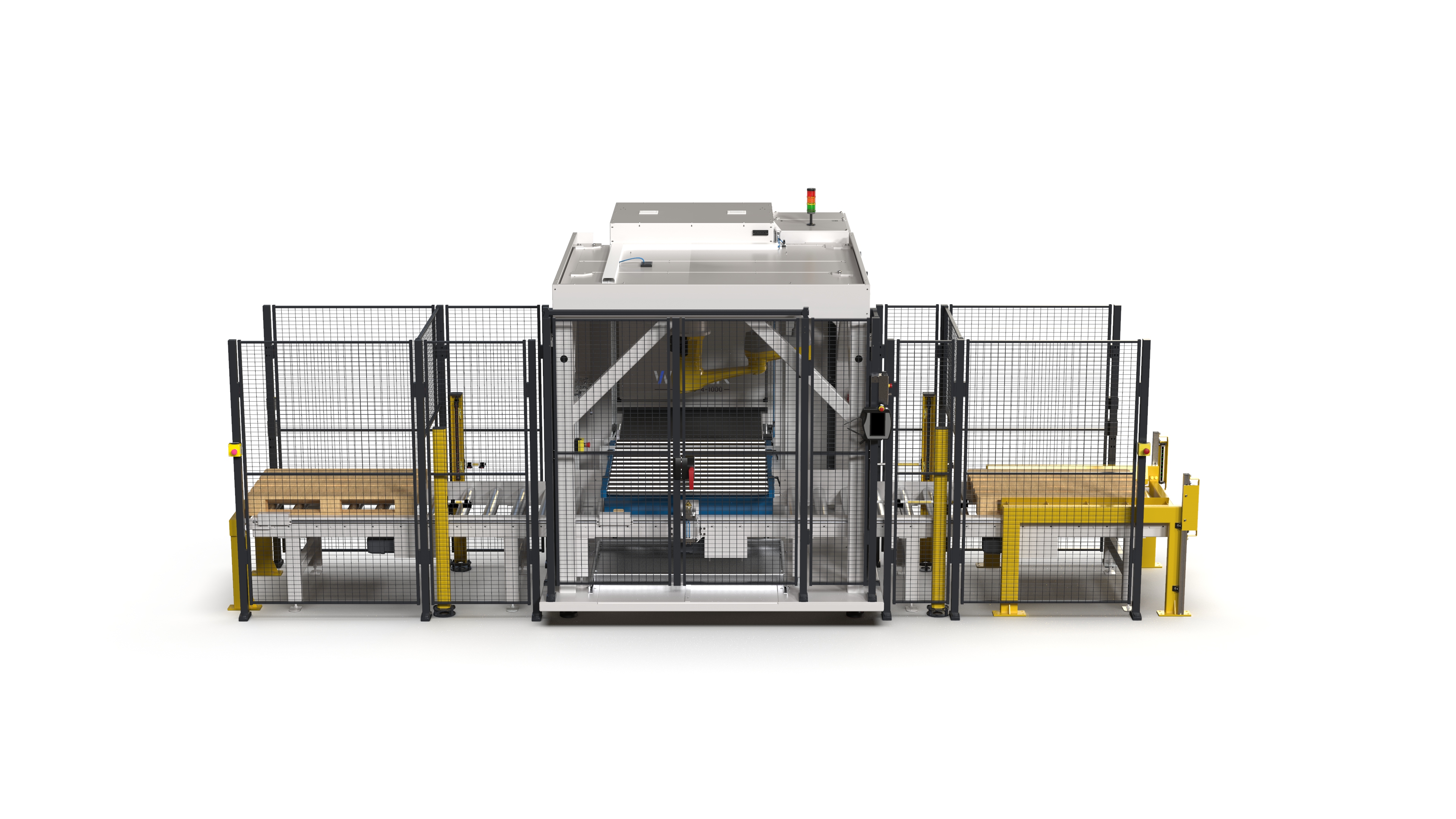

WEBER HS-4-1000

The adaptable handling system is designed as a complement to the subsequent process of the WEBER grinding machine and provides a seamless connection to the further processing steps of the workpieces. The system consists of an industrial robot, an optical recognition system, and a conveyor belt to locate and identify the incoming workpieces. These are fully automatically integrated into the system and intelligently placed on a Euro pallet.

Through the touch panel user interface "Rob Simple Control," the human-machine interface allows the operator to easily activate the teach mode and monitor the current process. Depending on the weight and geometry of the workpiece, it is intelligently gripped, with the system automatically recognizing the gripping point. Therefore, the operator does not need any programming or robotics skills.